NISSIN has been making contributions with the leading-edge technologies to a wide range of industries, including shipping, ice making and refrigerating warehouse, building air-conditioners, and special air-conditioners.

Nissin Refrigeration & Engineering Ltd. Product information

- Refrigeration

- Cascade refrigeration system

- Ammonia-alcohol refrigeration system

- Marine Refrigeration

- Marine Cold Storage

- Land-Based Refrigeration

- Land-Based Cold Storage

- Ice-Making

- Cooling slurry ice

- Freezing slurry ice

- Block-ice facilities

- Automatic plate-ice facilities

- Air-Conditioning

- Marine air-conditioner

- Land-Based air-conditioner

- Special Equipment

- Environmental testing constant temperature units

- Rocket air-conditioner

- Carbon dioxide fire extinguishing system

- LPG reliquefaction unit

- Vacuum drying system

- Heat exchanger/pressure system

- Cold trap

- Cargo heater

- LNG vaporizers

- Titanium heat exchanger for nuclear power plant

- Electronic NC system

- Job opportunities

- Contact

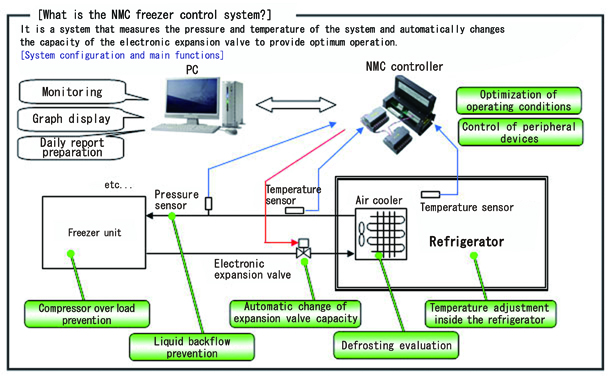

What is the NC system?

- Freezer protection function!

- It quickly senses overwork of the freezer and an abnormal flow rate of the refrigerant and takes action. It protects the freezer.

- Automatic learning function!

- It decides optimum control settings from the operating condition and makes automatic changes. The system is constantly kept in the best condition.

- Automatic defrosting function!

- Unlike previous systems, it senses a condition that requires defrosting and automatically performs defrosting.

- High-precision temperature control function!

- In addition to the conventional ON-OFF control, it is equipped with a function to adjust the temperature by changing the freezing power. It is capable of high-precision temperature adjustment without temperature fluctuations.

- High-efficiency cooling function!

- By automatically and quickly following changes in the condition of the cooling section, it constantly maintains an efficient cooling condition.

Automatic defrosting function

It automatically senses frosting on an evaporator (e.g., air-cooler) and outputs the defrost start signal.

Previous defrost starting method...

1. Defrosting is performed at pre-specified time whether the air-cooler is frosted or not.

2. Frosting is visually checked, and defrosting is performed.

3. An increase in the fan current value due to frosting of the air-cooler is sensed.

Nissin’s defrost timing judgment function

A reduction in the air-cooler power due to frosting is automatically sensed and defrosting is performed.

*This function can be realized only with Nissin’s NMC freezer control system, which constantly monitors the performance of expansion valves.

1. The controller adjusts the power of the electronic expansion valve in accordance with load conditions of the evaporator to perform optimum operation.

2. When frosting increases, the evaporator power decreases dramatically, causing the load on the expansion valve to decrease rapidly.

3. The controller senses the reduction in load and reduces the valve power.

4. When the valve power decreases below the lowered value in normal operation, a defrost signal is output from the relay output of the controller.

5. After the completion of defrosting, the end signal is input to the controller, and the valve power starts from the initial value.

Energy-saving effects of electronic expansion valves

According to the European and American literature, the electronic expansion valve is expected to have energy-saving effects of “25% in efficiency of the evaporator” and “20 to 30% in power consumption of the compressor” compared to temperature expansion valves even if it is used in a freezing warehouse in a high temperature range such as grade C.

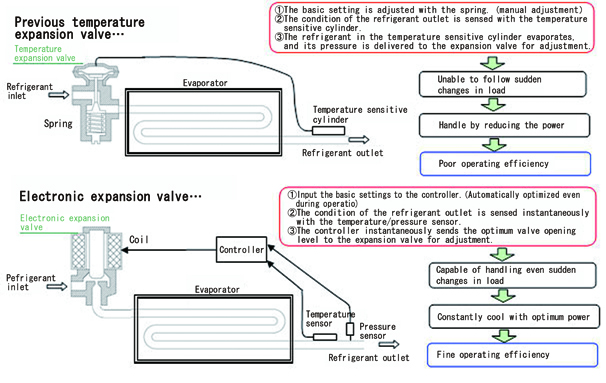

Reasons why the electronic expansion valve is energy-saving

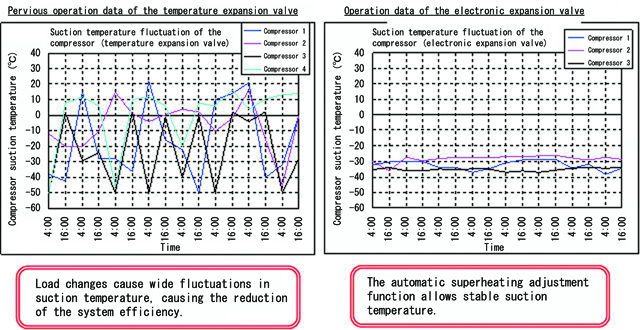

Verification by freezer operation data of deep-sea tuna longline fishing boats

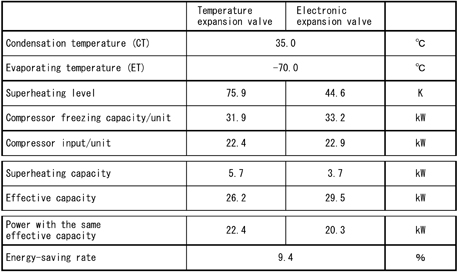

Energy-saving rate of the electronic expansion valve system

Heart of the NC system! “NMC controller”

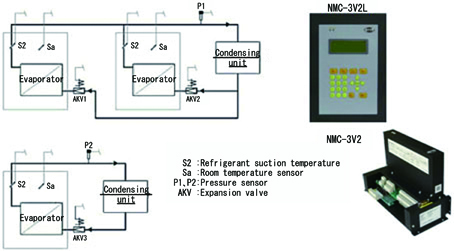

“NMC-3V2L (with indicator), NMC-3V2 (PC connection type)” for controlling three expansion valve systems

There are a type that is equipped with a LCD indicator and operation keys (NMC-3V2L) and a type that is operated from the PC (NMC-3V2).

A single controller allows the expansion valve control and temperature control of three systems.

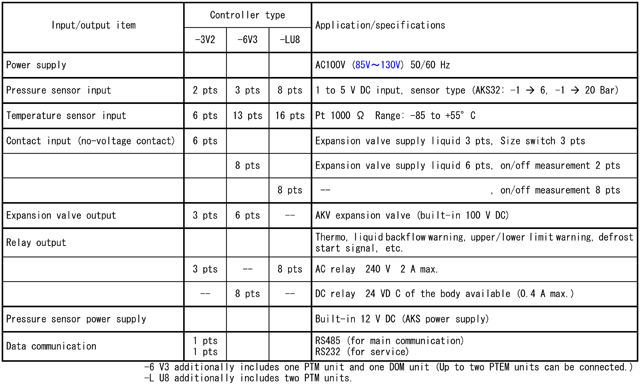

Input/output of the NMC controller

“NMC-6V3” for controlling six expansion valve systems

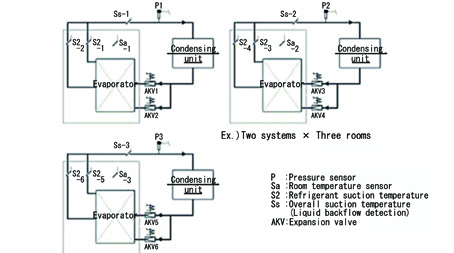

The six expansion valves can be set for multi-purpose use as 2 systems × 3 rooms, 3 systems × 2 rooms, or 6 systems × 1 room according to the usage.

PTM: temperature and pressure measurement module

DOM: relay output module

“NMC-LU8” for data measurement

The data measurement unit for the monitoring software is used to measure the pressure and temperature data of the freezing equipment. The pressure sensor input terminal can be used to convert output signals of various data, such as current, into voltage for measurement. The contact input is used in measurement of operating conditions for example.

Replacement of the previous controller with the NMC controller

- EKS (TQ valve controller)

The addition of a pressure sensor and the replacement of the expansion valve are required. The existing temperature sensor can be used.

- NCM controller

The pressure sensor needs to be replaced. The existing expansion valve and temperature sensor can be used.

- NCC controller

The existing pressure sensor, expansion valve, and temperature sensor can be used.

Monitoring software

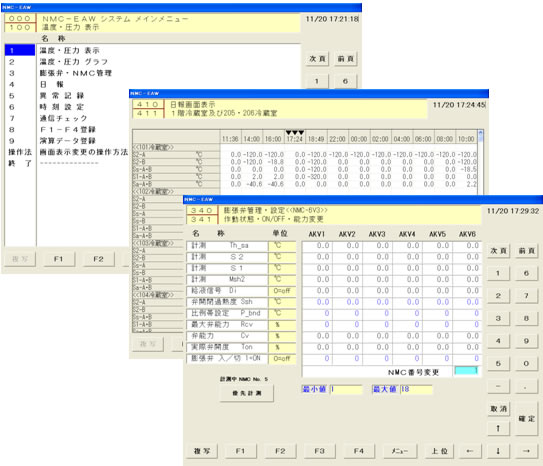

Package software NMC-EAW

The EAW software is freezer monitoring software that inherits the functions of the touch panel that has been sold since 1991 and has been improved for Windows PC. It supports touch-key operations on a panel computer and keyboard operations on a desktop/laptop computer.

This software contains various functions including the management of expansion valves, settings, graphs, and daily reports.

Set values and operating conditions are continuously recorded as excel data (CSV file).

The data of a maximum of 30 NMC controllers are measured at a rate of 1 sec/unit. The on-screen data update has been greatly improved from the previous system (NC system). Though there is no graphic representation screen, the display screen is designed according to the system to be delivered; hence, the screen is configured specifically for the system.

Data reproduction software

The graphs and daily report data of the NMC-EAW software can be simultaneously viewed on similar screens on multiple computers in the same network. The data can be copied as excel data (CSV file) for utilization.

NC-POW software

Software is manufactured for individual freezing equipment as a monitoring system for the entire equipment, including the acquisition of information from the sequencer built into the freezing equipment. The graphic screen adopted as the main screen allows the operating status of the equipment to be visually grasped, allowing precise setting changes for the expansion valves.

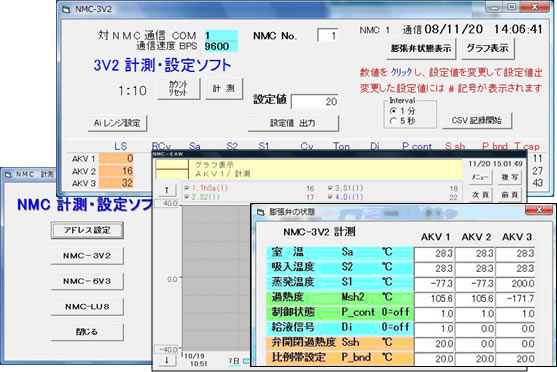

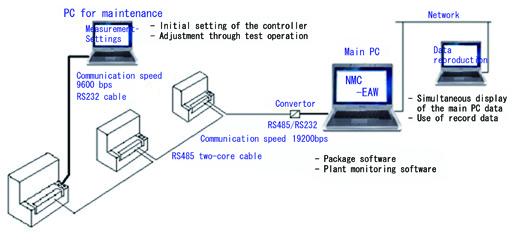

“Measurement and Setting Software” for maintenance

The NMC controller has two types of serial communication ports and allows simultaneous use of the maintenance PC and the main PC. The maintenance PC with the measurement and setting software installed can be connected to the RS232 port to use it one to one with the controller. At the same time, the “Display of Expansion Valve Condition” and the “Graph Display” allow the confirmation of the operating conditions of the expansion valves and setting value changes.