Ice-Making | Shape is essential in cooling

Nissin Refrigeration & Engineering Ltd. Product information

- Refrigeration

- Cascade refrigeration system

- Ammonia-alcohol refrigeration system

- Marine Refrigeration

- Marine Cold Storage

- Land-Based Refrigeration

- Land-Based Cold Storage

- Ice-Making

- Cooling slurry ice

- Freezing slurry ice

- Block-ice facilities

- Automatic plate-ice facilities

- Air-Conditioning

- Marine air-conditioner

- Land-Based air-conditioner

- Special Equipment

- Environmental testing constant temperature units

- Rocket air-conditioner

- Carbon dioxide fire extinguishing system

- LPG reliquefaction unit

- Vacuum drying system

- Heat exchanger/pressure system

- Cold trap

- Cargo heater

- LNG vaporizers

- Titanium heat exchanger for nuclear power plant

- Electronic NC system

- Contact

1. What is slurry ice?

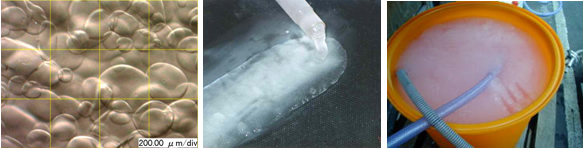

Slurry ice is liquid mixed with 0.1 to 0.5-mm spherical ice and is similar to snow melting partly.

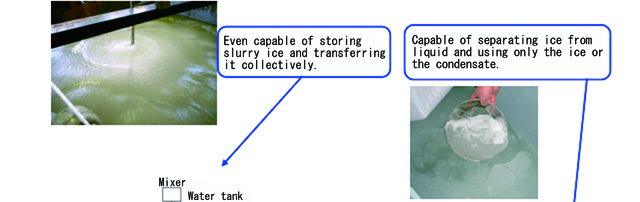

The ratio of ice contained in the liquid (called ice concentration) can be adjusted to the usage. At the exit of a manufacturing system, the adjustment can be made within the range of 0 to 30%, if the slurry ice is stored in a cold hatch or tank, the ratio can be approximately 40% at the maximum, and if the ice is separated from the liquid, the ratio can be increased to approximately 80% at the maximum.

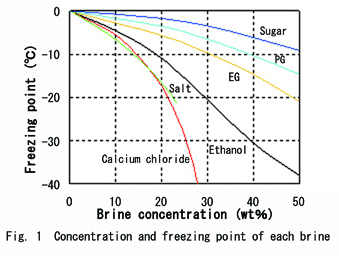

Slurry ice uses seawater or brine as the unprocessed liquid. Ice cannot be manufactured with clear water.

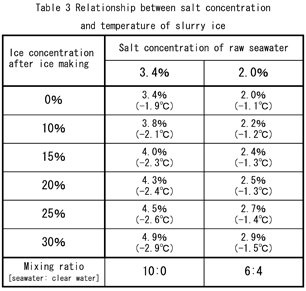

The temperature of slurry ice is slightly lower than the freezing point of the seawater or brine that is used as the unprocessed liquid.

2. Overview of the slurry ice manufacturing system

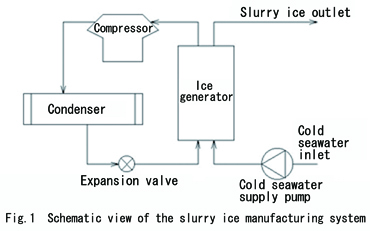

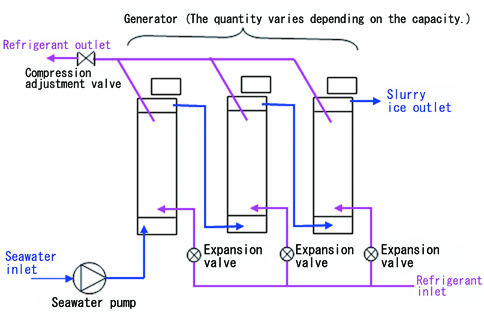

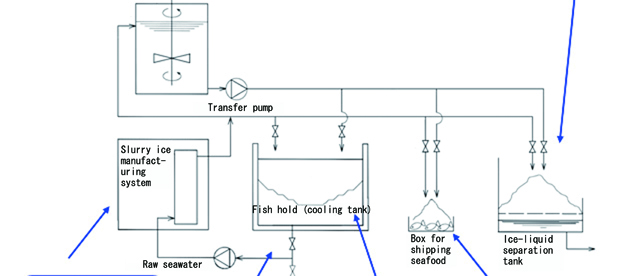

The schematic view of the slurry ice manufacturing system is shown in the right figure.

The device that manufactures slurry ice is called ice generator. Seawater is supplied with the seawater feed pump to the ice generator. The ice generator is supplied with a refrigerant through the compressor, condensor, and expansion valve. This refrigerant is used to cool the seawater to generate fine ice in it and eject it from the slurry ice outlet.

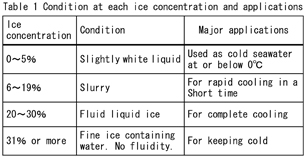

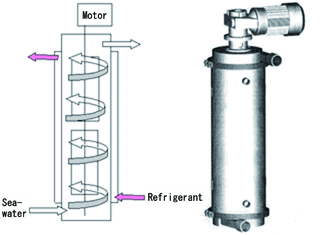

The ice generator has a dual-tube structure, where a refrigerant is supplied in the gap between the outer tube and the inner tube to cool down the seawater running inside the inner tube. A scraper is provided inside the inner tube. When this scraper turns, the fine ice generated inside the inner tube is taken into the seawater.

The longer the ice generator is, the higher the ice-making capacity the ice generator has.

There are seven types of length. If the ice-making capacity of the longest type is insufficient, increase the quantity of units.

3. Manufacturing method of slurry ice

1) Circulating ice-making method

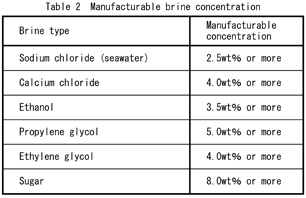

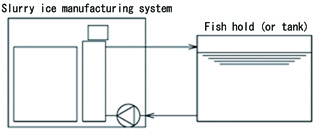

The required volume of unprocessed liquid is stored in a cold hatch (or a tank), and the unprocessed liquid is circulated between the cold hatch and the slurry ice manufacturing system to gradually adjust the ice concentration to the required one.

The manufacturing system is often reduced in size; a certain length of time is required until the required ice concentration is reached.

When transferring slurry ice after manufacture, a mixer device is required in the cold hatch.

Fig. 6: Overview of the circulating method

2) Direct method

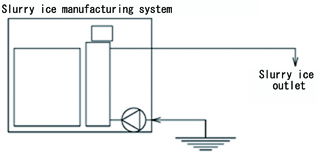

Slurry ice is adjusted to the required ice concentration upon ejection of the unprocessed liquid from the manufacturing system. The supply of slurry ice of the required ice concentration can be started in a short time (approximately 15 min). Depending on the operation method, the cold hatch (or a tank) for unprocessed liquid becomes unnecessary. However, the manufacturing system is often larger than that of the circulating method. However, by preliminarily cooling the brine to be supplied, the manufacturing system can be made smaller or the supply volume can be increased as well.

Fig. 8: Overview of the direct method

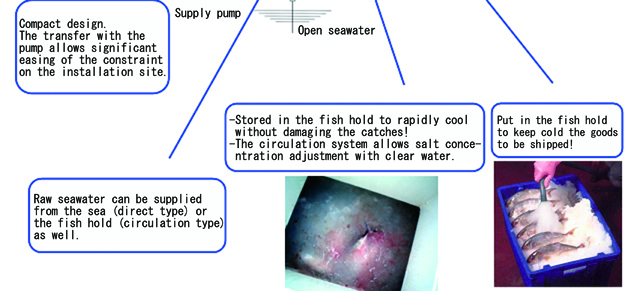

4. Usage of slurry ice in the fishing field

5. Benefits of use on a fishing boat

- - Since the liquid contains ice...

- - The temperature rise when catches are thrown in can be kept low.

- - Since the ice is fine...

- - It does not damage the surface of catches.

- - It rapidly cools down catches.

- - Since the ice is made from seawater...

- - Ice costs are unnecessary.

- - Since the evaporating temperature of the refrigerant is high...

- - The power consumption is lower than previous ice-making machines.

- - Since the ice is fluid...

- - It can be transferred with a pump, allowing energy conservation.

6. Example of cooling fishes with slurry ice

1) Cooling of horse mackerels

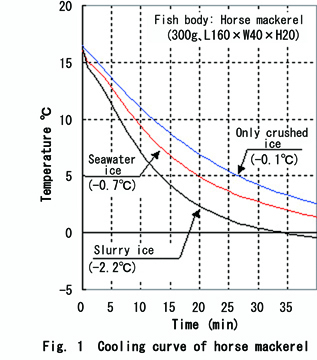

Sufficient volumes of (1) slurry ice made from seawater, (2) seawater ice made by mixing crushed ice and seawater, and (3) crushed ice were respectively put into three cold boxes. Horse mackerels were put into these boxes and the cooling time was measured (Fig. 1).

In this test, the high thermal conductivity of slurry ice was added with the difference in liquid temperatures. The time until the central temperature reaches 2°C was 22 min for slurry ice, 36 min for seawater ice, and 46 min for crushed ice only. This shows that the cooling rate of slurry ice was 1.6 times as high as that of seawater ice and twice as high as that of crushed ice.

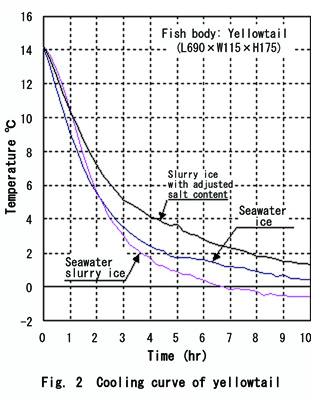

2) Cooling of yellowtails

Sufficient volumes of (1) seawater ice made by mixing salt-content-adjusted seawater with crushed ice (salt content 2.7%), (2) slurry ice made from seawater (salt content 3.7%), and (3) slurry ice made from salt-content-adjusted seawater (salt content 2.0%) were respectively put into three cold boxes. Yellowtails were put into the boxes, and the cooling time was measured (Fig. 2).

In this test, comparison of the cooling time until the central temperature of the fish body reaches 5°C showed that the time of the seawater slurry ice and that of seawater ice were mostly the same, and salt-content-adjusted slurry ice took approximately 1.5 times as long as the seawater ice. As for the appearance after cooling, the yellowtail of the seawater slurry ice was discolored and had a poor color, while the yellowtail of the salt-content-adjusted slurry ice was more colorful than that of the seawater ice and was beautifully finished. As for clouding of the eyes after keeping the fishes cold for 24 hours, severe clouding was observed with the yellowtails of the seawater slurry ice and the seawater ice, while that of the salt-content-adjusted slurry ice showed nearly no clouding.

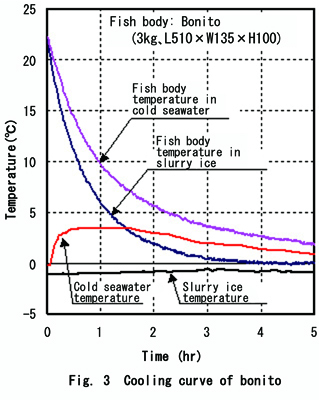

3) Cooling of bonitos

(1) Salt-content-adjusted cold seawater and (2) salt-content-adjusted slurry ice were respectively put in the cold hatches of three fishing boats. Bonitos that were caught were put into the hatches, and the cooling time was measured (Fig. 3).

In this test, comparison of the cooling rate until the temperature of the center of the fish body reaches 5°C shows that slurry ice is approximately twice faster than the cold seawater. The condition of the fish bodies indicated no wearing by ice, which was a concern; however, the blackening of the body, which is observed when a bonito is cooled down excessively, was observed after rapid cooling. However, when the water in the cold hatch was replaced with normal cold seawater, the condition became the same as the one under normal conditions.

4) Cooling of sardines

Sardines that were caught in fixed nets were used to carry out a test on eye clouding with different conditions of salt content and liquid temperature of slurry ice.

This test showed that eye clouding does not occur if the salt content is the same or lower than that of seawater; however, if the liquid temperature falls -1°C or lower, clouding occurred regardless of the salt content. However, when the sardines were taken out of the slurry ice after clouding occurred and were stored in ice, clouding stopped occurring.

These results indicate that the fishes’ freezing temperature is generally approximately -1.5°C; however, the eyes seem to be frozen at approximately -1°C. This suggests that the eye clouding in the case of cooling with slurry ice occurred because only the eyeballs were frozen. Hence, it can be surmised that after rapidly cooling the fish bodies, if the fishes were taken out of the slurry ice and kept cold in a usual manner, clouding disappears and returns to a clear condition.

5) Cooling of firefly squids

The test carried out with firefly squids showed that after rapid cooling, when the squids were stored at or below 0°C, the body color changed from clear color to white, ruining its commercial value. The body color became white when the salt content became lower than 1% as expected.

6) Cooling of sand eels

The test on sand eels showed similarly to firefly quids that after rapid cooling, when the sand eels were stored at or below 0°C, the body color becomes white. However, even if the salt content was not reduced significantly, the quality of the appearance was not likely to deteriorate.

7) Cooling of alfonsinos

Alfonsinos were immersed in salt-content-adjusted slurry ice for two hours to cool them. The test shows no body color deterioration in any salt content; the clouding of the eyeballs was observed slightly at or below -1°C as expected. For alfonsinos, the particularly large eyeballs probably led to the damage and cracks inside the eyeballs of the alfonsinos immersed in -2°C or lower slurry ice because of the freezing. This damage was not resolved even the storage temperature was raised after cooling.